Pwht of carbon steels

pwht of stainless steels and nickel alloys

pwht of heat-treatable alloys

pwht of exotic materials and superalloys

case studies on material-specific pwht.

Post Weld Heat Treatment (PWHT)

Post weld heat treatment is a post welding heating process used to improve the properties of the weldment. Heat treatment following welding may be carried out for one or more of three fundamental reasons (1):

to achieve dimensional stability in order to maintain tolerances during machining operations or during shake-down in service

to produce specific metallurgical structures in order to achieve the required mechanical properties

to reduce the risk of in-service problems such as stress corrosion or brittle fracture by reducing the residual stress in the welded component

the need for pwht is normally driven by code requirements. For section i these requirements can be found in section pw-39 requirements for postweld heat treatment.

Post weld heat treatment (pwht) is a thermal process that is performed on welded materials after welding to reduce residual stresses and improve the welded joint’s mechanical properties. Residual stresses occur during welding due to heat input, leading to flaws such as distortion, cracking, and defects in the welded joint. Pwht relieves these stresses and enhances the joint’s toughness, ductility, and strength. The process involves heating the welded material to specific temperatures for a defined period and controlled cooling. Pwht parameters depend on the material, welding process, and desired joint properties. Industries such as oil and gas, petrochemical, and aerospace commonly use pwht for welded joints exposed to high temperatures, pressure, and extreme conditions.

Post-weld heat treatment (pwht) of steel structures is a process that involves reheating the welded joints to a certain temperature and holding them for a specified time. The purpose of pwht is to improve the mechanical properties and reduce the residual stresses of the weld and the heat-affected zone (haz). Pwht can also prevent hydrogen-induced cracking (hic), which is a type of brittle fracture that can occur in high-strength steels due to the presence of hydrogen, stress, and a susceptible microstructure. There are different types of pwht, such as stress relieving, normalizing, tempering, and annealing. The choice of pwht depends on the material type, thickness, welding procedure, and service conditions of the steel structure.

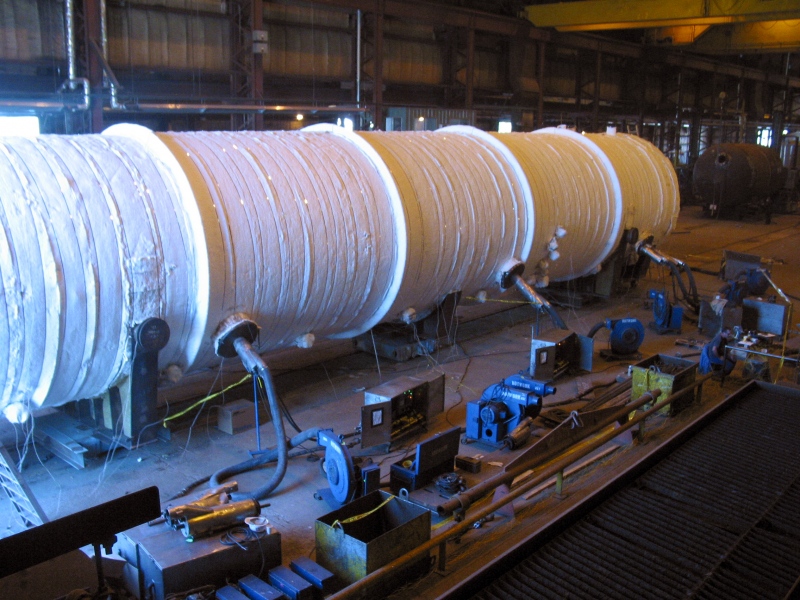

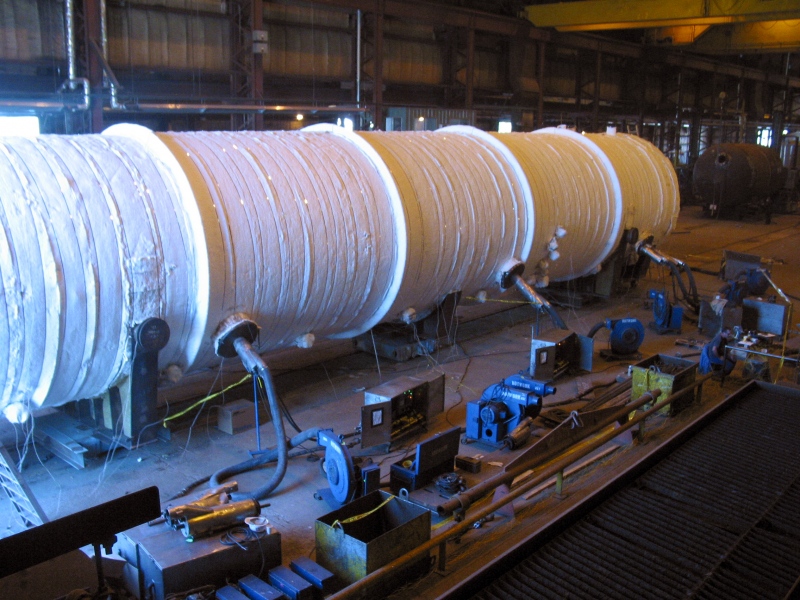

The post weld heat treatment (pwht) service offered by the jst-group helps improve the weld microstructure, which in turn reduces the residual stresses that often develops during the welding stage. We are one of the leaders in post-weld and post-heat treatment for steel and metal fabrication, with a team of highly experienced specialists. Our team specializes in a myriad of pwht services for industries like construction, pressure piping, bridges, offshore platforms, storage tanks, pressure vessels, petrochemical plants, refineries, etc. If your requirement isn’t listed, please feel free to contact us.