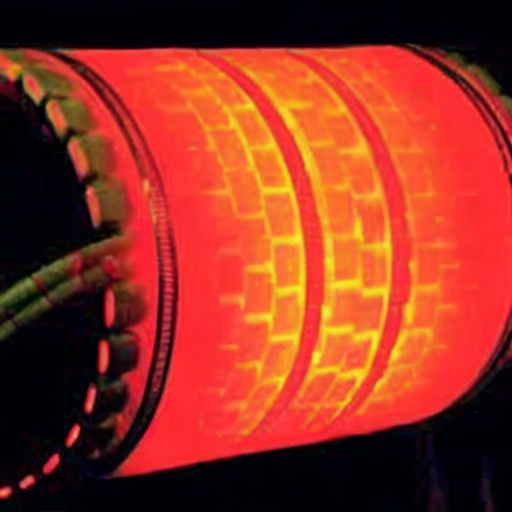

Post-Weld Heat Treatment , or PWHT for short, is a critical step in the welding process that often gets overlooked. You know, when metals are joined by welding, it's not just about melting and fusing them together; there’s a whole lot of stress and changes in the microstructure going on inside the material that can affect its performance down the line. So what exactly is PWHT? Well, it's a method where we apply heat to a welded component but at a controlled rate - this ain't your regular bonfire heat! We're talking precise temperatures here. The metal needs to be heated to a specific temperature (and nope, it’s not random; each metal type has its own set of rules) and then held at that temperature for a given amount of time before slowly cooling it down to room temperature. Now you might be asking yourself: "Why bother with all this heating and cooling jazz?" Here's the kicker - during welding, the high temperatures can create areas of high hardness known as 'heat-affected zones,' which can make the metal brittle and susceptible to cracking (and nobody wants that!). Plus, there're residual stresses from all

Many folks often ask, "What's the secret to enhanced structural integrity in metals?" Well, it ain't rocket science! The answer lies in a process known as Post Weld Heat Treatment (or PWHT for short). So, let's dive into this fascinating topic and discover its power! Now, you might be wondering - what exactly is PWHT? Simply put, it’s a process that involves heating metal workpieces right after welding them. Sounds simple? It does indeed. But don’t let its simplicity fool you! This technique has profound effects on the properties of metals. Alright then, moving on to why this method is so significant. When we weld metals together (particularly high-strength alloys), stress tends to build up around the welded area due to rapid cooling. These residual stresses can lead to cracking or distortion of the metal piece over time. Not cool at all, huh? On the other hand, when we apply PWHT techniques properly, these stresses are significantly reduced or even eliminated altogether! The systematic heating and slow cooling during post-weld heat treatment relieve those tensions built up during welding. However (and here comes the important part), not

Welding is a crucial part of many manufacturing processes and having the right post weld heat treatment (PWHT) can optimise your welds significantly. Yet, it can be hard to know where to start! This article will help you understand how PWHT works and how you can use it to improve your welding results. First off, let's discuss what PWHT actually is. It's a process of heating a welded joint after welding has been completed in order to reduce residual stresses, eliminate cracking and increase strength. The temperatures used vary depending on the material being welded but generally range from 400°C - 650°C for steels and 500°C - 700°C for aluminium alloys. These temperatures are applied for specific time intervals which depend on the thickness of the material being treated. Furthermore, there are several advantages that come with using PWHT: improved fatigue life which reduces the risk of cracks forming over time, better corrosion resistance, improved ductility and higher impact strength. However, it's important to remember that any form of heat treatment carries some risks such as warping or distortion due to stress relief so make sure you do your research before deciding whether or

Post weld heat treatment (PWHT) can be a powerful tool in increasing the performance of metals and alloys. But, unlocking its benefits isn't always so simple! It requires careful consideration of the material being treated, the welding process used and the temperatures applied to achieve an optimal result. To start, it's important to understand how PWHT works. In essence, PWHT applies a gradual increase in temperature following welding in order to relieve any residual stresses within the materials. This relieves internal strain that could lead to cracking or other types of failure if left untreated. The process also homogenizes the grain structure which makes for more consistent mechanical properties across the entire welded area. By doing this, PWHT enhances fatigue strength and reduces susceptibility to corrosion and hydrogen embrittlement. Moreover, there are some factors which should be taken into account when deciding whether or not to use PWHT on a given project. For example, one should consider which type of metal is involved and what kind of environment it will be exposed to once completed; both can affect the effectiveness of PWHT treatments. Additionally, it's important to remember that higher temperatures can cause distortions

Post Weld Heat Treatment (PWHT) is a process used to extend the life of welded products. It involves heating the weld area and then cooling it at a controlled rate to reduce stress and residuals stresses in the welded joint. This helps to increase the strength, fatigue resistance and corrosion resistance of the joint! PWHT can be applied to many types of metals including aluminum and steels, as well as some plastic materials. However, it is not always necessary for all welding processes and depends on the type of material being joined. There are several advantages that come with PWHT. Firstly, it reduces the risk of cracking or premature failure due to high residual stresses in a welded joint. Secondly, it improves the ductility and toughness of the material which allows for increased load carrying capacity. Furthermore, this process can also reduce distortion caused by welding, resulting in improved dimensional accuracy of components after welding. Lastly, PWHT increases corrosion resistance by eliminating hydrogen embrittlement from welds or reducing its effects. Despite these benefits there are also some drawbacks associated with Post Weld Heat Treatment such as cost, complexity and potential damage during heating or

Optimizing your manufacturing process with post-weld heat treatment can be a time-consuming and daunting task. But, if done right, it can have a huge positive impact on the quality and efficiency of your products! In fact, there're many ways to go about this that'll help you get the most outta the process. Firstly, make sure you check for any potential weld defects before beginning the heat treatement. If any are found they must be corrected or else risk damaging the product in the furnace. Secondly, ensure that the correct temperatures are reached at each stage of treatment. Too low and performance may suffer; too high could cause cracking or distortion in the material! Furthermore, use appropriate quenching methodologies to avoid overcooling of parts. In additon to this, consider using preheating when practicable - as this can improve hardness and strength by ensuring homogenous cooling from inside out (especially for large sections). Additionally, employ proper surface protection measures such as coatings or waxes to prevent oxidation during heating cycles. Finally, keep good records of all procedures used so that any future treatments can be replicated effectively. Also don't forget to monitor temperature profiles during each step