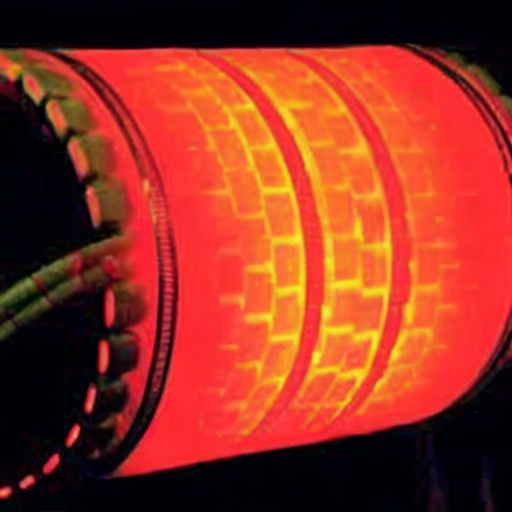

Post Weld Heat Treatment (PWHT) is a process used to extend the life of welded products. It involves heating the weld area and then cooling it at a controlled rate to reduce stress and residuals stresses in the welded joint. This helps to increase the strength, fatigue resistance and corrosion resistance of the joint! PWHT can be applied to many types of metals including aluminum and steels, as well as some plastic materials. However, it is not always necessary for all welding processes and depends on the type of material being joined.

Post Weld Heat Treatment (PWHT) is a process used to extend the life of welded products. It involves heating the weld area and then cooling it at a controlled rate to reduce stress and residuals stresses in the welded joint. This helps to increase the strength, fatigue resistance and corrosion resistance of the joint! PWHT can be applied to many types of metals including aluminum and steels, as well as some plastic materials. However, it is not always necessary for all welding processes and depends on the type of material being joined.

There are several advantages that come with PWHT. Firstly, it reduces the risk of cracking or premature failure due to high residual stresses in a welded joint. Secondly, it improves the ductility and toughness of the material which allows for increased load carrying capacity. Furthermore, this process can also reduce distortion caused by welding, resulting in improved dimensional accuracy of components after welding. Lastly, PWHT increases corrosion resistance by eliminating hydrogen embrittlement from welds or reducing its effects.

Despite these benefits there are also some drawbacks associated with Post Weld Heat Treatment such as cost, complexity and potential damage during heating or cooling stages if not performed properly. In addition to this, depending on what materials you are working with different temperatures may be required which could result in higher costs or longer processing times when compared to other heat treatment methods such as annealing or tempering.

In conclusion, Post Weld Heat Treatment is an effective way to extend product life but should only be used when necessary due to its potential drawbacks mentioned above. It is important however that whatever method you choose for heat treatment must adhere to safety regulations and industry standards as dictated by governing bodies such as ASME/ANSI codes for proper quality assurance results!