Overcoming Prosthetic Challenges with 3D Printing Solutions

Introduction

Prosthetic limbs have been a game-changer for individuals who have lost a limb due to injury or medical conditions. However, traditional prosthetics often come with their own set of challenges, including limited customization, discomfort, and high costs. Fortunately, advancements in technology, particularly in 3D printing, have revolutionized the field of prosthetics, offering innovative solutions to overcome these challenges.

Customization for Enhanced Comfort

![]()

One of the major challenges faced by prosthetic users is the lack of customization options. Traditional prosthetics are often mass-produced, resulting in a one-size-fits-all approach. This can lead to discomfort and limited functionality. With 3D printing, prosthetics can be tailored to fit the unique needs and preferences of each individual. The ability to create personalized prosthetics ensures a better fit, improved comfort, and enhanced mobility.

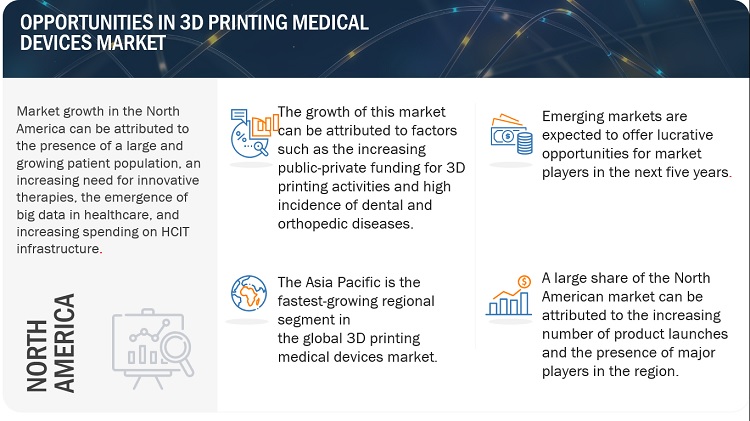

Cost-Effective Solutions

Traditional prosthetics can be prohibitively expensive, making them inaccessible to many individuals. 3D printing has significantly reduced the cost of manufacturing prosthetics. By utilizing affordable materials and streamlined production processes, 3D printed prosthetics offer a cost-effective alternative. This affordability opens up opportunities for more people to access high-quality prosthetics, ultimately improving their quality of life.

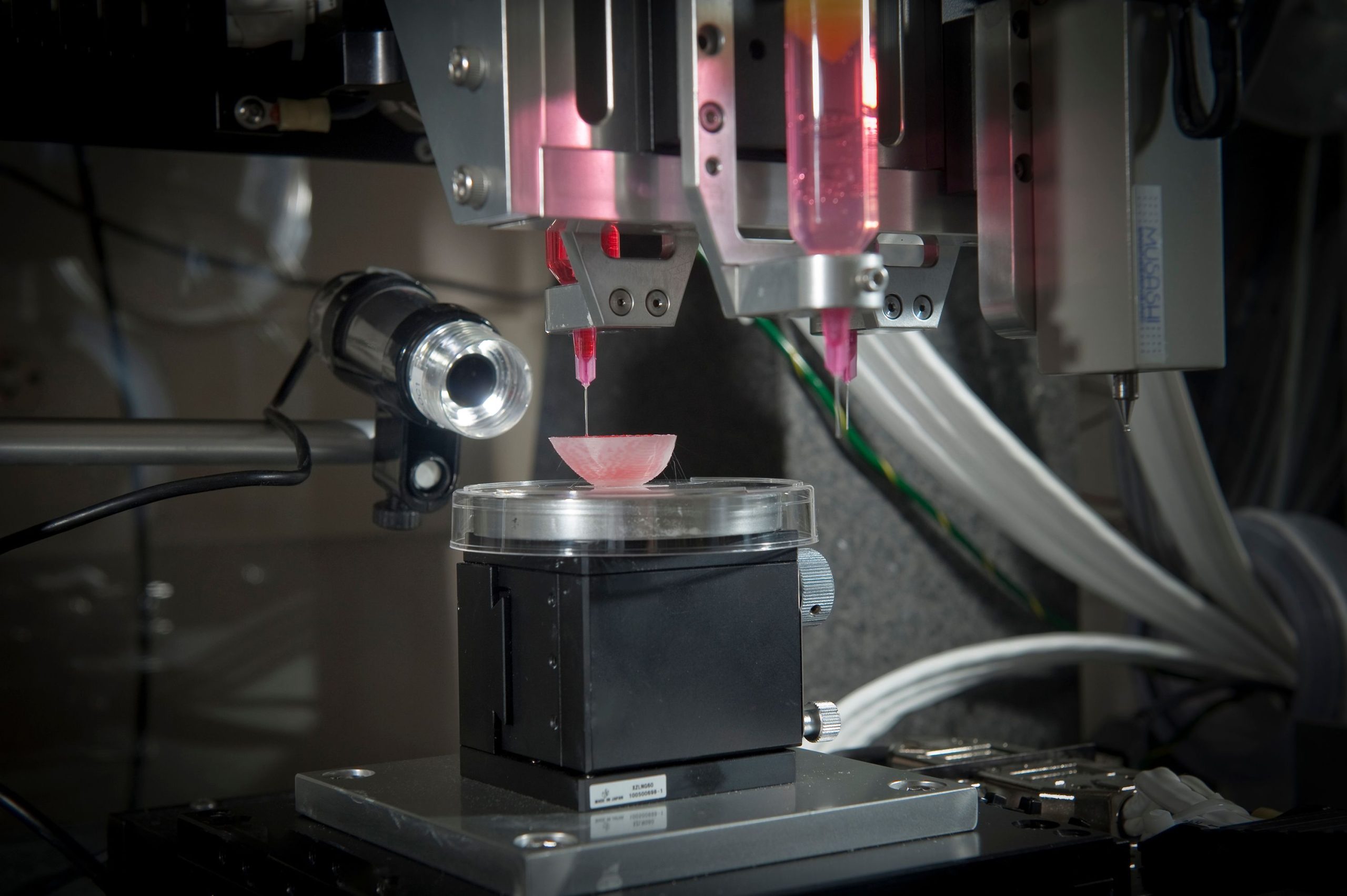

Rapid Prototyping and Iteration

Developing prosthetics traditionally involves a lengthy and complex process. With 3D printing, rapid prototyping and iteration are made possible. This means that designers and engineers can quickly create and test multiple iterations of a prosthetic design, making necessary adjustments along the way. This accelerated development process allows for faster innovation and the ability to address specific challenges faced by prosthetic users.

Lightweight and Durable Materials

Traditional prosthetics are often heavy and cumbersome, limiting the wearer’s mobility and comfort. 3D printing enables the use of lightweight and durable materials, such as carbon fiber and nylon, in the production of prosthetics. These materials offer strength and flexibility while significantly reducing the weight of the prosthetic. The result is a more comfortable and functional prosthetic that allows for greater freedom of movement.

Summary

3D printing has emerged as a game-changer in the realm of prosthetics, enabling the creation of highly personalized and functional limb replacements. This blog post explores the various ways in which 3D printing solutions have helped overcome challenges in the prosthetic industry. From enhanced customization and affordability to improved comfort and accessibility, 3D printing has opened up new possibilities for amputees worldw moved here ide. Join us as we delve into the exciting advancements and success stories that highlight the transformative power of 3D printing in prosthetics.

- Q: What are some challenges faced with prosthetics?

- A: Some challenges faced with prosthetics include limited customization options, high costs, and discomfort due to poor fit.

- Q: How can 3D printing help overcome these challenges?

- A: 3D printing allows for highly customizable prosthetics, reducing costs and improving comfort by creating a better fit.

- Q: What are the benefits of using 3D printing for prosthetics?

- A: The benefits of using 3D printing for prosthetics include faster production times, lower costs, improved functionality, and increased patient satisfaction.

- Q: Can 3D printing create prosthetics for different body parts?

- A: Yes, 3D printing can create prosthetics for various body parts, including limbs, hands, fingers, and even facial prosthetics.

- Q: Are 3D-printed prosthetics as durable as traditional ones?

- A: While 3D-printed prosthetics may not be as durable as traditional ones initially, advancements in materials and printing techniques are constantly improving their strength and longevity.

- Q: How long does it take to 3D print a prosthetic?

- A: The time required to 3D print a prosthetic can vary depending on its complexity and size, but it typically ranges from a few hours to a couple of days.

- Q: Can 3D-printed prosthetics be adjusted or modified?

- A: Yes, one of the advantages of 3D-printed prosthetics is their adjustability. They can be easily modified or resized to accommodate changes in the wearer’s body or preferences.

- Q: Are 3D-printed prosthetics covered by insurance?

- A: Insurance coverage for 3D-printed prosthetics may vary depending on the specific insurance provider and policy. It is recommended to check with the insurance company to determine coverage options.

- Q: Can individuals without medical backgrounds create 3D-printed prosthetics?

- A: Yes, with the availability of