Advanced Techniques in 3D Printing: A Hands-On Guide

Introduction

3D printing has revolutionized the manufacturing industry, allowing for the creation of complex and intricate designs with ease. While basic 3D printing techniques are widely known, there are advanced techniques that can take your prints to the next level. In this hands-on guide, we will explore some of these advanced techniques and how they can be implemented to enhance your 3D printing projects.

Multi-Material Printing

One of the most exciting advancements in 3D printing is the ability to print with multiple materials. This technique allows for the creation of objects with varying textures, colors, and even mechanical properties. By using a printer with multiple extruders or by employing post-processing techniques, you can achieve stunning results that were previously impossible.

Dual Extrusion

Dual extrusion is a technique that involves using two different materials simultaneously. This allows for the creation of objects with intricate patterns or supports that can be easily removed. For example, you can print a complex model with a water-soluble support material that dissolves when submerged in water, leaving behind a clean and detailed final product.

Mixing Filaments

Another approach to multi-material printing is mixing filaments. By combining different filaments with varying properties, you can create objects with unique color gradients or even materials with custom mechanical properties. This technique opens up a world of possibilities for designers and engineers.

Support Structures

Support structures are an essential part of 3D printing, especially when printing complex geometries. However, traditional support structures can be difficult to remove and may leave marks on the final print. Advanced techniques offer solutions to these challenges.

Tree Supports

Tree supports are a type of support structure that mimics the branching structure of a tree. This technique reduces the amount of material used for supports and makes them easier to remove. Tree supports provide better accessibility to the model and result in a cleaner final print.

Dissolvable Supports

Dissolvable supports are made from a material that can be dissolved in a specific solvent, leaving behind.

Summary

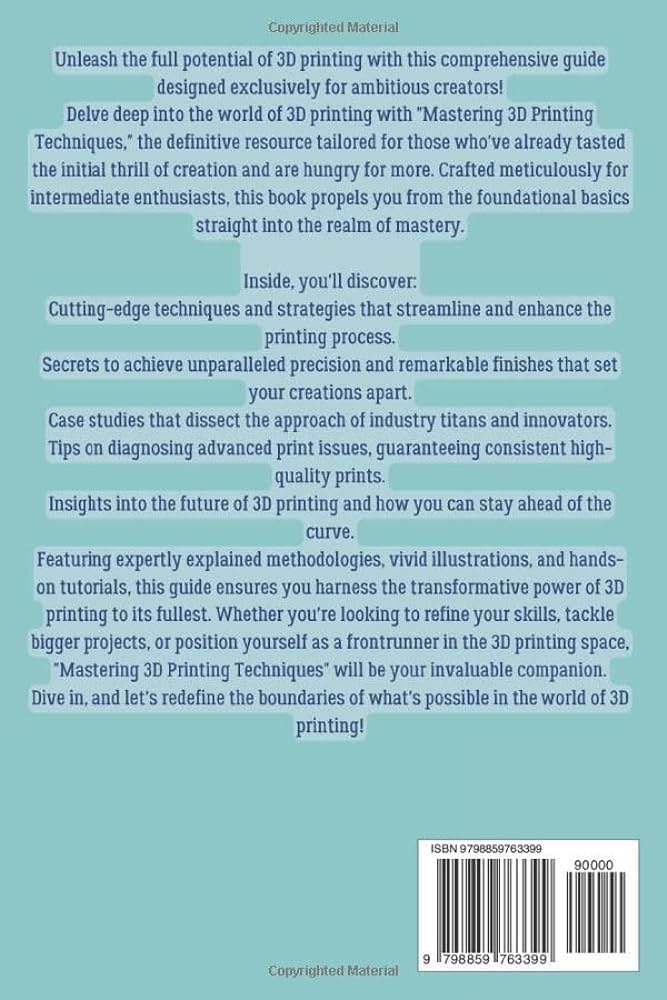

Advanced Techniques in 3D Printing: A Hands-On Guide is a comprehensive resource that delves into the intricacies of 3D printing. Written by industry experts, this guide provides step-by-step instructions and practical tips for mastering advanced techniques in the field.

The book covers a wide range of topics, including advanced modeling techniques, material selection, post-processing methods, and troubleshooting common issues. It also explores the latest advancements in 3D printing technologies, such as multi-material printing, bioprinting, and metal 3D printing.

Whether you are a hobbyist looking to expand your skills or a professional seeking to push the boundaries of 3D printing, this guide will equip you with the knowledge and techniques needed to take your creations to new heights. With detailed explanations, accompanied by illustrations and real-world examples, you will gain a deep understanding of the advanced techniques and their applications.

By the end of this guide, you will have the confid more helpful hints ence and expertise to tackle complex 3D printing projects, unleash your creativity, and produce high-quality prints that stand out from the crowd.

- Q: What is 3D printing?

- A: 3D printing is a manufacturing process that creates three-dimensional objects by layering materials based on a digital design.

- Q: What are advanced techniques in 3D printing?

- A: Advanced techniques in 3D printing refer to the use of complex materials, intricate designs, and specialized processes to achieve higher levels of detail, functionality, and customization in printed objects.

- Q: What are some examples of advanced materials used in 3D printing?

- A: Examples of advanced materials used in 3D printing include carbon fiber composites, metal alloys, flexible and rubber-like materials, conductive filaments, and bio-compatible resins.

- Q: How can I improve the resolution and detail of my 3D prints?

- A: To improve resolution and detail, you can adjust the layer height, print speed, and nozzle size. Additionally, using finer quality filaments and optimizing the design for 3D printing can also enhance the final output.

- Q: What are some post-processing techniques for 3D printed objects?

- A: Post-processing techniques for 3D printed objects include sanding, painting, polishing, dyeing, and applying various coatings or finishes to improve the appearance, texture, and durability of the prints.

- Q: How can I optimize the strength and durability of my 3D prints?

- A: To optimize strength and durability, you can adjust the infill density, use stronger materials, add reinforcement structures, and ensure proper cooling and layer adhesion during the printing process.

- Q: What are some advanced applications of 3D printing?

- A: Advanced applications of 3D printing include medical and dental implants, aerospace components, architectural models, customized prosthetics, fashion accessories, and intricate art pieces.

- Q: Are there any limitations to advanced 3D printing techniques?

- A: Yes, some limitations include higher costs associated with advanced materials and equipment, longer printing times for complex designs, and the need for specialized knowledge and skills to utilize advanced