Solving Common 3D Printing Problems: A Workshop Series

Introduction

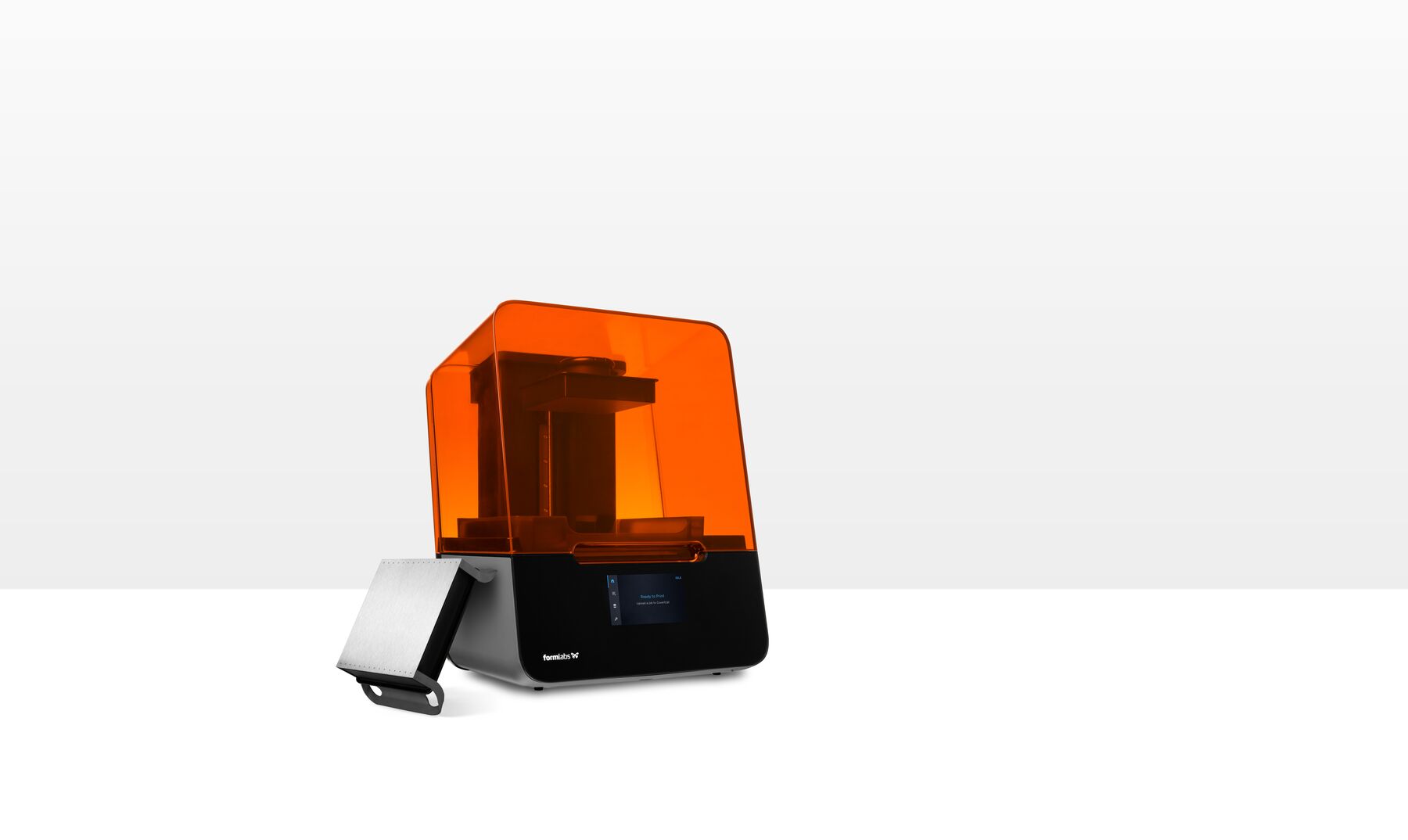

3D printing has revolutionized the manufacturing industry, allowing individuals and businesses to create complex objects with ease. However, like any technology, it comes with its own set of challenges. This workshop series aims to address and solve common 3D printing problems, helping enthusiasts and professionals alike to optimize their printing process and achieve better results.

Understanding Filament Issues

One of the most common problems in 3D printing is filament-related issues. This section will cover topics such as filament diameter, moisture absorption, and filament storage techniques.

Filament Diameter

Incorrect filament diameter can lead to under or over-extrusion, resulting in poor print quality. This section will provide tips on measuring filament diameter accurately and adjusting printer settings accordingly.

Moisture Absorption

Moisture absorption can cause filament to become brittle and lead to print failures. This subsection will discuss the importance of storing filament in a dry environment and suggest effective moisture prevention techniques.

Filament Storage

Proper storage of filament is crucial to maintain its quality. This part will explore different storage options, such as vacuum-sealed bags and desiccant containers, to ensure filament longevity.

Troubleshooting Print Quality

Print quality issues can be frustrating, but with the right knowledge, they can be easily resolved. This section will focus on troubleshooting common print quality problems, such as layer adhesion, stringing, and warping.

Layer Adhesion

Poor layer adhesion can result in weak and fragile prints. This subsection will discuss techniques to improve layer adhesion, including adjusting print settings, using adhesives, and optimizing bed temperature.

Stringing

Stringing occurs when the printer leaves unwanted strands of filament between printed parts. This part will provide tips on reducing stringing, such as adjusting retraction settings and using filament-specific temperature profiles.

Summary

Our workshop series aims to equip participants with the knowledge and skills to troubleshoot and solve common 3D printing problems effectively. Each workshop will focus on a specific issue and provide step-by-step guidance on identifying the root cause and implementing the appropriate solutions.

Topics covered in the series include:

- Print bed adhesion issues

- Layer shifting and warping

- Under-extrusion and over-extrusion

- Nozzle clogging and filament jams

- Print quality and surface finish problems

Whether you are a beginner or an experienced 3D printing enthusiast, this workshop series will provide valuable insights and techniques to enhance your printing experience. Join us as we unravel the mysteries of 3D printing problems an investigate this site d empower you to create flawless prints every time.

- Q: My 3D printer is not extruding filament properly. What should I do?

- A: Check if the nozzle is clogged and clean it if necessary. Also, ensure that the filament is loaded correctly and not tangled. Adjust the extrusion temperature and speed settings if needed.

- Q: The printed object is not sticking to the build plate. How can I improve adhesion?

- A: Make sure the build plate is clean and free from any debris. Apply a suitable adhesive such as glue stick or 3D printing bed adhesive. Adjust the bed leveling and temperature settings for better adhesion.

- Q: I’m experiencing warping or curling of printed parts. How can I prevent this?

- A: Ensure that the print bed is heated to the appropriate temperature for the filament being used. Use a brim or raft to increase the surface area of the printed object. Consider using a heated enclosure or adding a draft shield to minimize temperature fluctuations.

- Q: The printed object has visible layer lines. How can I achieve a smoother finish?

- A: Adjust the layer height to a smaller value for finer details. Increase the number of top and bottom layers to improve surface smoothness. Experiment with different print speeds and cooling settings. Consider post-processing techniques such as sanding or applying a filler primer.

- Q: My 3D printer is making strange noises during printing. What could be the cause?

- A: Check if any mechanical components, such as belts or pulleys, are loose or damaged. Lubricate the moving parts if necessary. Ensure that the filament is feeding smoothly without any obstructions. If the issue persists, consult the manufacturer or a professional technician.