What are Types of Shoring: Choose among 9 Methods

by Admin

Posted on 08-06-2024 04:27 PM

Choosing the right

shoring

method is critical to ensuring safety, stability and efficiency at your job site. You need to consider factors like soil conditions, the scale of excavation, adjacent structures, and project timeline to determine which shoring technique is optimal for your needs. Whether you require basic bracing and lagging for minor excavations or a complex network of tiebacks and struts to secure deep trenches in unstable soil, understanding the basic types of shoring and their applications will allow you to make you help choose and avoid potentially dangerous or costly mistakes.

With the proper shoring solution in place, you can proceed confidently with your excavation, knowing the surrounding area is properly supported.

With the proper shoring solution in place, you can proceed confidently with your excavation, knowing the surrounding area is properly supported.

As you could probably guess, there is a good deal of shoring types that are used in construction. Since we are capable of a near-infinite amount of buildings and structures, our shoring techniques have to follow suit. The following are some of the most commonly used shoring methods: secant pile shoring sheet piles contiguous pile shoring while this is by no means a comprehensive list, these are some of the most common types of shoring that you will come across. These are staples of the shoring world and are used daily in the construction of new buildings and infrastructure.

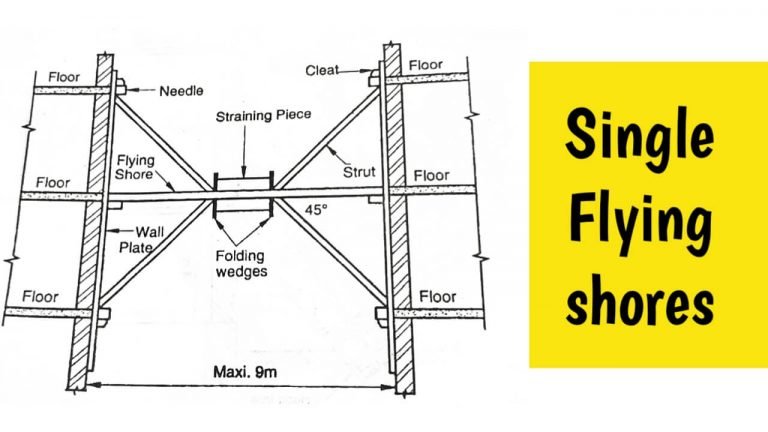

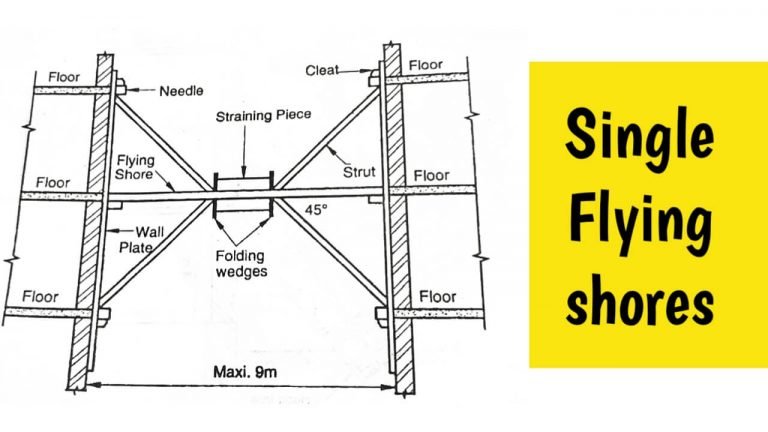

All types of shoring are suited to propping up walls that bulge or crack and need repairs. Combinations of shoring methods also work when an adjacent structure requires demolition, or when you're cutting openings into walls. Horizontal flying shores are ideal for support of walls in two separate buildings when a structure in between the buildings is slated for demolition. Dead shores prop up roofs and floors when the bottom segment of a wall has been removed to create an opening or to rebuild a defective load-bearing wall. For added safety during wall-cutting, some contractors install raking shores in addition to dead shores for greater insurance against falling walls.

Overview of Shoring in Construction

Construction shoring is a vital practice in the construction industry, crucial for ensuring the stability and safety of structures during the building process. This article aims to provide a comprehensive overview of construction shoring, discussing its definition, applications, types, and key considerations. What is construction shoring?

construction shoring refers to the process of supporting a building, structure, or excavation with shores (props) when it is in danger of collapse or during repairs and alterations.

Shoring is used to temporarily support a structure while it is under construction, repair, or alteration. It’s a critical safety measure that prevents collapses and ensures the integrity of the building.

Shoring is used to temporarily support a structure while it is under construction, repair, or alteration. It’s a critical safety measure that prevents collapses and ensures the integrity of the building.

There are multiple shoring approaches used in construction. Depending on the structure, they each have different applications that work best in certain conditions. Listed below is an overview of eleven different techniques:.

Types of Shoring Systems

Shoring refers to the process of supporting a structure, excavation, or trench to prevent collapse and ensure the safety of workers. Various types of shoring systems are utilized depending on the specific requirements and conditions of the project. Here are some common types of shoring:.

Shoring is an integral part of the construction process, both for increasing the stability of a structure and for providing adequate support for a scaffolding system. There are several different types of shoring that can be used for different purposes. Cantilever shoring: cantilever shoring is a type of shoring that uses an i-beam or other beam. To support one end while the other end protrudes beyond its supports. This type of shoring is often used in projects that require additional strength such as bridge construction and large concrete pours. Deadman shoring: deadman shoring involves using a large weight to hold down one end of the shoring.

Shoring is the process of supporting a structure temporarily to prevent collapse or failure during construction or repair work. Shoring is an essential part of construction projects involving excavation, underpinning, or propping up existing structures. Different types of shoring systems are used depending on the situation and soil conditions.

Shoring is used to support the beams and floors in a building while a column or wall is removed. In this situation vertical supports are used as a temporary replacement for the building columns or walls. Trenches - during excavation, shoring systems provide safety for workers in a trench and speed excavation. In this case, shoring should not be confused with shielding. Shoring is designed to prevent collapse where shielding is only designed to protect workers when collapses occur. Concrete structures shoring, in this case also referred to as falsework, provides temporary support until the concrete becomes hard and achieves the desired strength to support loads.

Although people unfamiliar with trenching operations often interchange the terms shielding and shoring, there are significant differences. Excavation shoring utilizes equipment and materials to prevent the walls from collapsing. In contrast, shielding systems use a shield or box to protect workers in case of a collapse.

Hydraulic shoring consists of using hydraulic pistons which are pumped outward till they press against the walls of the trench. Usually, prefabricated struts and aluminum or steel wale systems are used in this method. Hydraulic shoring is very popular as it is faster and easier to use. Other methods are generally used for long term applications and larger excavations. Reasons for the popularity of hydraulic shoring: it is more safe than timber shoring. The workers need not go into the trench to install or to remove hydraulic shoring. Hydraulic systems can be easily installed by a worker as they are light.