Steel shoring Pros and Cons

by Admin

Posted on 08-06-2024 04:27 PM

Environmental concerns and city requirements almost always go together (items 1 and 2 above). As property in urban areas becomes limited due to high demand, all available properties, no matter the below-grade condition, are developed if they comply with all city rules and regulations. Most of these sites are around below-grade city infrastructures, sensitive utilities, and high-ground water tables that are not allowed to be de-watered or on or near contaminated sites.

shoring

-1-300x169.png" align="right" alt="joists" style="max-width:70%; margin:4px;" />

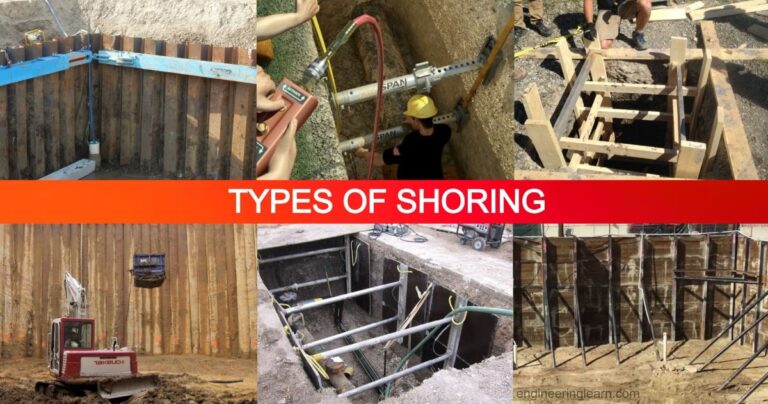

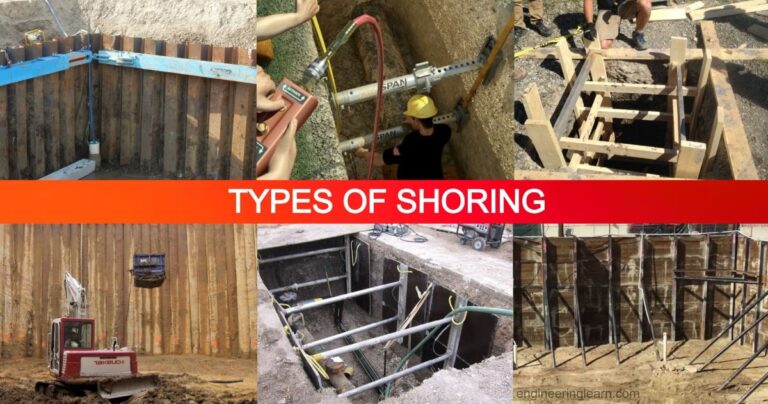

Shoring design needs to become complex to address these issues and concerns. Soil-cement mixing (smx), also called deep soil mixing (dsm), was developed in japan and europe; smx finally came to the united states about fifty years ago.

Such types of shoring consist of vertical members known as dead shores supporting horizontal member known as needles. The needles transfer the weight of the wall to the dead shores. This types of shoring are provided to serve the following purposes: to repair the broken and bulging lower part of the wall. To rebuild or deepen the existing foundation. To make the large opening at a lower part of the existing wall. Holes are made in the wall at the required and appropriate height. Needles, which are made of the thick wooden section or of steel, are inserted in the holes. Each needle is supported at its two way ends by vertical posts or dead shores.

Typically used when the vertical face of the excavation is less than 20 feet, cantilever shoring consists of soldier piles and lagging. Soldier piles are constructed with steel i-beams. Wood or steel plate lagging is then placed between the i-beams to hold the earth in place.

What is Concrete Shoring

Building construction commonly uses shoring to support concrete floors until hardening provides self-support. This process is repeated on each level of on a multistory building. Efficiency becomes the determining factor in selecting the right shoring equipment.

When the best system is matched with each job, less manpower is needed for setup and tear down, increasing job profitability. A few things should be considered when choosing shoring for building construction. Things like site space and transport affects the job. Some sites don’t have the space for shoring equipment that comes in on multiple trucks. If space is at a premium, finding shoring that fits by design onto one flatbed truck is an advantage.

When the best system is matched with each job, less manpower is needed for setup and tear down, increasing job profitability. A few things should be considered when choosing shoring for building construction. Things like site space and transport affects the job. Some sites don’t have the space for shoring equipment that comes in on multiple trucks. If space is at a premium, finding shoring that fits by design onto one flatbed truck is an advantage.

In addition to used shoring towers and used slide rail systems , eiffel trading’s online marketplace sells additional equipment including used concrete formwork , used pile breakers , and more. When it comes to used materials, our inventory ranges from used f-shape barrier wall , to used steel pipe pile , to used hdpe pipe , and everything in between. All of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free. Ready to sell your used heavy equipment or construction material? list your products today for free on eiffel trading’s online marketplace.

Another common trench shoring method is h- and i-beam shoring, also called soldier pile wall shoring. This method uses prefabricated h or i sections that are vibrated or slid into holes in the ground. Concrete panels then slide in between these beams. This method is best when working in trenches between 4 and 15 feet deep but can be reinforced when working in deeper spaces.

Concrete Shoring pros and cons

Wellmade is a popular shoring scaffold provider in china. If you are looking for a reliable supplier and manufacturer of shoring scaffolds, wellmade is the best place for you. Our shoring scaffold frames mainly export to the usa, australia & europe countries. The shoring scaffold system is used widely in hi-load requirement concrete formwork and construction. Wellmade shoring scaffold is manufactured for different applications. You may use a shoring scaffold in a wide range of construction such as concrete slab & beam formwork, bridge shoring scaffolding and infrastructure construction, hi-load scaffolding tower, and many more. Wellmade shoring scaffold is made from od 60mm and od 48mm scaffold steel tubes.

High load capacity shoring posts and shoring systems for the construction of slabs, bridge decks, pier caps, tunnel vaults or any other concrete structure that requires the use of shoring.

Used an emergency replacement for a foundation, our aurora temporary shoring service helps keep your construction operations going until a permanent shoring solution is available. Soldier pile walls, trench shoring, and soil nail walls are three options when considering temporary shoring in aurora and denver. Soldier pile walls are an incredibly quick construction method that consists of h-shaped steel piles, concrete holes, and wood lagging. Depending on the range of excavation, tiebacks/anchors may be needed. Soldier pile walls are flexible and can be designed for large surcharge loads. Trench shoring comes in several different forms, but in its basic form for temporary shoring in denver entails walls lining the side of a trench filled with stabilizers in the middle.

Chance® helical tiebacks are a pre-engineered mechanical anchoring system for permanent and temporary earth retention. The success of the helical anchor tieback system is based on decades of similar use of chance® anchors in the electric utilities industry. Capacities up to 200,000 pounds per anchor are obtainable with this instant tieback shoring method.

A pile is installed at regular intervals (5 to 8 ft, 1. 5 to 2. 4m) and timber or other lagging is installed as the excavation progresses. These can be cantilever excavation shoring systems or supported by ground anchors or internal bracing.

Raking shores are used as temporary support structures for walls within a building that are not structurally sound. This type of shoring is also called inclined shoring, as inclined posts (typically positioned at an angle between 45-75 degrees) provide lateral support to the unstable structure to minimize damage. A structure may require just a simple leaning post, or something as complicated as a group of rakers combined and anchored into position.