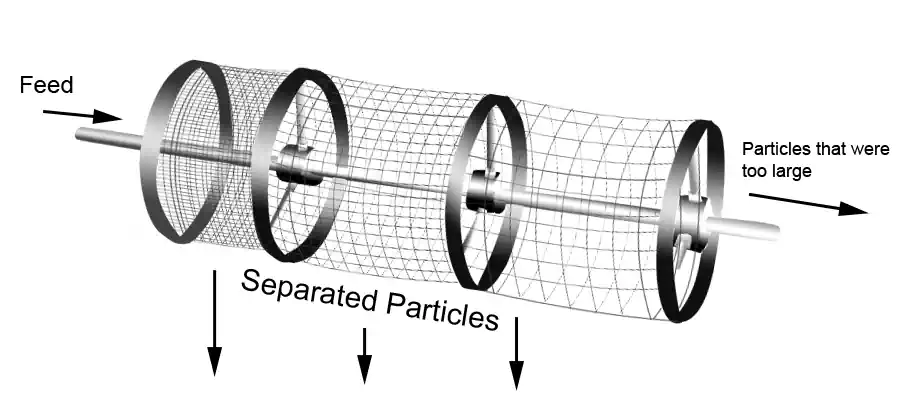

A trommel screen is a sorting machine used for the separation of mixed MSW (Municipal Solid Waste). It is a cylindrical device with perforated screens that rotate along its longitudinal axis. As the waste enters the trommel screen, it is separated into different fractions based on its size, shape, and other physical characteristics. The most common fractions produced by the trommel screen are the light and bulky fraction and the small and heavy organic fraction.

Trommel Separation into "fractions"

The light and bulky fractions include materials such as plastics, paper, cardboard, and other lightweight materials. These materials are separated from the heavier materials by the trommel screen due to their lighter weight and size being too large to pass through the holes around the perimeter of the trommel cylinder. The small and heavy organic fraction includes materials such as food waste, yard waste, and other organic materials. These materials are separated from the other fractions because of their higher density and smaller size.

The trommel screen is a highly efficient and cost-effective way of separating mixed MSW into its component fractions. It is a versatile machine that can be used for sorting a variety of materials and is capable of producing high-quality outputs. Additionally, the trommel screen is easy to operate, maintain, and clean, making it an ideal choice for waste sorting operations.

Value of a trommel for mixed MSW sorting

A trommel screen is a valuable tool for the separation of mixed MSW into its component fractions. It is capable of producing two distinct fractions, the light and bulky fraction and the small and heavy organic fraction. This machine is highly efficient, cost-effective, and easy to operate, making it an ideal choice for waste sorting operations.

What You Should Know About Trommel Screen Waste Separation

A trommel screen is a piece of equipment that separates material based on the size of the particles. These types of screens can be used in a variety of applications. If you're considering purchasing one, there are several things that you should know before you make your purchase.

Disadvantages of trommel screens

If you are a trommel screen operator, you must be aware of the disadvantages of this type of screening equipment. However, there are some things you can do to prevent damage to the equipment. Also, you should make sure you are properly trained.

Trommels are widely used to separate waste materials. They are also often used to recover valuable minerals from raw materials. For instance, they are commonly used to separate the old from gold-bearing gravel. Many trommels are also used in recycling plants.

Construction details of a trommel screen

A trommel screen is a cylindrical rotary screen. It is typically inclined at a downward angle. The screen is also equipped with perforation cavities. These cavities are designed to facilitate the separation of materials of different densities.

The disadvantages of a trommel screen include its inefficiency and blinding. This can cause additional maintenance and even halt production. In addition, the cost of replacing parts can be high.

Trommels are also prone to plugging. This occurs when the materials in the screen become backed up. There are a number of different designs for trommels, including curved screens, series and parallel configurations, and concentric screens.

.

.

By Ceicgrp10, CC BY-SA 3.0, Link.

Typical applications of a trommel screen

A trommel screen is an effective tool in the separation and recycling of waste. It can be used in a variety of industries including composting, landfill, and fertilizer plants.

A trommel screen is a rotating drum that collects materials and separates them into smaller fractions. This makes it possible to process and recycle waste in a shorter period of time. In addition, a trommel screen can save valuable time, money, and energy.

Trommels are made in many different sizes and designs to meet the needs of the specific application. For instance, compact trommels are best suited for small yards or urban environments. Larger models are equipped with interchangeable drums.

Typical applications of a trommel screen are sludge separators, landfill and compost, construction and demolition (C&D) recycling, and topsoil and green waste recycling. They are also used in the oil and gas industry to recover crude oil and gas.

The screening efficiency of a trommel depends on the size of the material and the rotational velocity of the drum. Smaller particles are screened through a thin mesh, while larger particles stay inside the trommel.

Common types of trommel screens

Many different industries rely on trommel screens. These machines separate waste into two or three components. This process helps reduce solid waste sent to landfills.

The composting industry, food processing, and construction and demolition recycling are some of the most common applications for trommel screens. They are also used in iron mining. However, before deploying trommel screen machinery in a workplace, employees should be properly trained. If they have medical conditions, they should consult their base's safety office before operating any equipment.

A typical trommel screen system is composed of a screening sub-system and two conveyor belts. A rotating sieving drum is usually included. There are many variations on this design. Some models come equipped with attached stacking conveyors. These add considerable weight and cost to the machine.

Another option is to use a trommel with a tension screen drum. This type of trommel can be more effective than a drum with an open mesh. Larger granules can be retained inside the trommel.

Safety issues with trommel screens

There are certain safety issues that should be kept in mind when using trommel screen waste separation. These include the type of material being separated, its moisture content, and its bulk density.

It is also important to consider the safety of the operators. Before using the machine, be sure to visit the responsible safety officer to understand all the possible hazards when working on this equipment ad to get the right personal protective equipment (PPE).

The trommel is a cylindrical separation device that is commonly used to separate various materials. Its design is simple and is frequently employed in organic waste processing.

It is used to sort compost and other materials. There are several variations of this screening device. Each model has different materials, and it is important to choose the one that will meet your needs.

The trommel is primarily used for composting, but it is also used in alternative applications of municipal solid waste separation. Depending on the type of material being separated, the trommel can be inclined or horizontal.

Conclusion to What You Should Know About Trommel Screen Waste Separation

Trommel screens are an effective and efficient method for separating mixed MSW and recyclable materials, allowing the organic pulp to be used to feed the anaerobic digestion process and plastics to be recycled into new plastic.

The screens are also fast, reliable, and cost-effective, making them a great option for recycling and waste management companies.

With their ability to reduce the amount of waste sent to landfills, trommel screens are an eco-friendly option that can help to create a cleaner, greener world.