How Does a Hydrogen Generator Work?

by Admin

Posted on 23-06-2023 04:51 PM

At the col du palet 2600 m high, above the city of tignes, mahytec in collaboration with its partners, powidian, gest’hydrogene, waechter energies, is implementing its expertise to offer a suitable solution of hydrogen storage. Two h2 tanks with a working pressure of 30bar and a volume of 850l each, i. E 4. 5 kg hydrogen in total will allow the refuge of the col du palet to give up their fuel generator and switch to clean energy in line with the environment. These tanks lighter than their steel counterparts, could easily be helicopter-borne.

Mahytec was responsible for the entire hydrogen chain and subcontracted with powidian.

Mahytec was responsible for the entire hydrogen chain and subcontracted with powidian.

How to Compress Methane Gas to Liquid

Today, hydrogen is transported from the point of production to the point of use via pipeline and over the road in cryogenic liquid tanker trucks or gaseous tube trailers. Pipelines are deployed in regions with substantial demand (hundreds of tons per day) that is expected to remain stable for decades. Liquefaction plants, liquid tankers, and tube trailers are deployed in regions where demand is at a smaller scale or emerging. Demonstrations of hydrogen delivery via chemical carriers (e. G. , in barges) are also underway in large-scale applications, such as export markets. At the point of hydrogen use, additional infrastructure components that are commonly deployed include compression, storage, dispensers, meters, and contaminant detection and purification technologies.

Compressors are needed to move and store hydrogen. From the point at which hydrogen is produced to the point where it is consumed, our wide compression portfolio supports many applications across the hydrogen value chain. This includes: the gathering of green hydrogen from electrolysis; grey and blue hydrogen produced by steam methane or autothermal reformers (smrs/atrs); sending hydrogen through pipelines; compressing hydrogen to the pressure levels required for storage caverns/tanks, ammonia production, e-fuels production, vehicle fuelling stations; liquefaction for vessel transport facilities; and feeding it into gas turbines or other downstream and petrochemical processes. Our portfolio gives you more technology choices for the optimum solution for your project-specific requirements, considering….

By francesco la porta and hidenobu usuda hydrogen presents opportunities as a clean energy source, either used as storage or as fuel in mobility, or as a feedstock in refineries and petrochemical processes. But there are many challenges to overcome, many of which revolve around the cost-effectiveness and reliability of hydrogen storage and transportation technology. Kawasaki heavy industries (khi) recently conducted a pilot study on hydrogen transportation. A new khi carrier transported hydrogen 9,000 km from the eastern coast of australia to kobe, japan. Of the many challenges examined during the sea voyage, the most vital was testing the atlas copco gas and process centrifugal compressor for boil off gas (bog) that ensures hydrogen remains chilled at -253° c in liquid form.

Hydrogen is an ultra-light gas that occupies a substantial volume under standard conditions of pressure, i. E. , atmospheric pressure. In order to store and transport hydrogen efficiently, this volume must be significantly reduced. Hydrogen is the lightest gas in the entire universe. One liter of this gas weighs only 90 mg under normal atmospheric pressure, which means that it is 11 times lighter than the air we breathe. A volume of around 11 m3 (which is the volume of the trunk of a large utility or commercial vehicle) is needed to store just 1 kg of hydrogen, which is the quantity needed to drive 100 km.

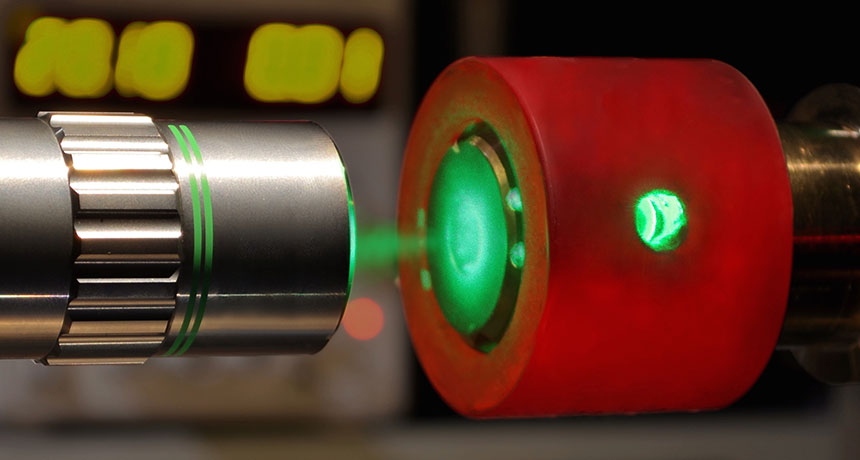

Compressed hydrogen is the gaseous state of hydrogen energy. Here, hydrogen gas is tapped into a compressor inlet. It’s an intensive process that highly impacts the cost. Hydrogen can then be stored in cylinders or gas tubes with pressures between 200 and 500 bar. Compost overwrapped pressure vessels (copvs ) are the most preferred method for the storage of compressed hydrogen. However, copvs are lightweight and are more suitable for large-scale transportation and storage of hydrogen. There are four types of copvs: type 1: made of steel type 2: made of steel with a glass fiber or composite hoop overwrap type 3: made of a aluminum liner and fully wrapped in carbon fiber composite.

An international research team has developed a novel concept of gravitational energy storage based on buoyancy, that can be used in locations with deep sea floors and applied to both the storage of offshore wind power and compressed hydrogen. Called buoyancy energy storage technology (best), the proposed technology is defined as an alternative to pumped-hydro storage for coasts and islands without mountains that are close to deep waters. It consists of using stored renewable electricity to power a motor that lowers a compressed gas recipient and then generating electricity by releasing the compressed gas recipient to rise back to the surface through the water.